What is 3D printing and what are its origins?

The first chapter of the Complete Guide to 3D Printing – What is 3D Printing? Designed for anyone interested in 3D printing and interested in deepening their understanding of the evaluation of this technology. This chapter explains what 3D printing is, what benefits it brings, what its historical origins are and how this technology began to be widely used.

Preface

From the earliest days of mankind humans have produced physical products. The physical products developed by humans surround us wherever we go, in the tools we use, in the clothing we wear and in the buildings in which we live. Over the years, a variety of manufacturing methods have been developed which have given man the opportunity to expand his design, construction and manufacturing capabilities. The new methods of production have caused revolutions that have taken root in all areas of our lives (such as the Industrial Revolution).

3D printing is the current technological revolution in the world of manufacturing, which we are privileged to see today and experience its impact on all the different worlds of manufacturing. This technology opens up a whole new world of design and manufacturing possibilities that have never existed before.

What is 3D Printing

3D printing is a manufacturing method in which machines called 3D printers produce physical parts from a 3D file sent from a computer. The 3D file is layered by dedicated software. The layout instructions of the model are transferred from the computer to the 3D printer (some say “Tlat-Peset” in Hebrew) which builds the model layer by layer.

The advantages of 3D printing over other manufacturing processes

Unlike other methods for manufacturing products and parts;, 3D printing is an “additive” manufacturing method – Additive Manufacturing, or AM. This manufacturing method is based on scattering material in selected areas and adding layer upon layer until a finished model is created.

Until the invention of this method, the main method to manufacture complex parts was Subtractive Manufacturing, the “defective” manufacturing method. This method uses a volume of material (a lump of some material) and extracts the desired shape by removing material. For example: carving marble and stone sculptures or wood carving as has been done since ancient times, and the latest technologies such as CNC machines. The material reduction process has significant disadvantages, including material waste, increased heat production, chips, air pollution, etc.

3D printing allows the product to be built step by step and the material used only where it is required. The process usually saves material, pollutes less, improves manufacturing processes, saves time and solves various manufacturing constraints of complex parts.

3D Printing Origins

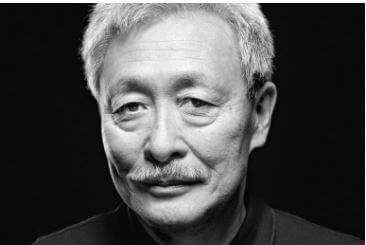

Although 3D printers are perceived as an innovative technology, 3D printing technology was developed about 40 years ago! As early as 1981, Dr. Hideo was promoted from the Bengoi Research Institute in Japan to create the first 3D model using a photofilament process.

Photofilmer is a solidification process of a liquid solution containing photopolymers – polymers which bond to each other following exposure to light of a certain wavelength. Kodma’s model was built using layers of liquid resin solution (similar to today’s SLA printers ) containing photopolymers that were spread on top of each other and hardened with the help of laser beams, each of which represented a layer in the 3D model (similar to the 3D printers we know today).

Hideo Kodama is the first to apply for a patent for the hardening of a photopolymer resin using laser beams.

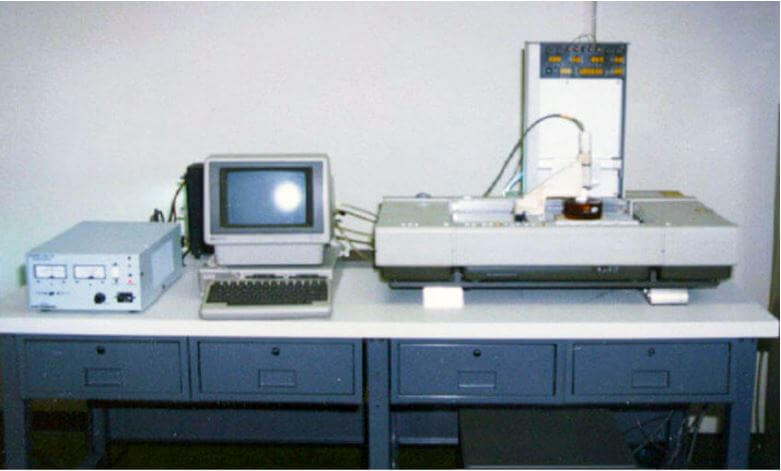

Four years later, Charles Hall, an American inventor, invented stereolithography. Stereolithography is a technology for firming polymeric materials using a computerized file projected using a beam or wave that causes the material to solidify in the desired areas. This is how the layers solidify one after the other according to the computerized file in order to create the designed three-dimensional model.

Charles Hall worked in the furniture and table covering industry. To make it harder to coat the top surfaces of the tables, use a UV lamp. The use of UV bulbs for hardening gave Hall an idea – the use of UV bulbs to make photopolymer solutions difficult and through them to produce customized products.

Hall began experimenting with this technology and in 1984 filed a patent application for this technology and claimed its name – stereolithography. The patent was issued in 1986 and in the same year Hall founded the company 3D Systems. 3D Systems launched its first product in 1988, the SLA-1 3D printer. Today, the company is one of the leaders in the production of industrial 3D printers, such as the ProX 500 using the SLS method.

From history to present days and future of 3D Printing

Over the years, the 3D printing technologies and production opportunities they bring have evolved. Whereas in the past it was a very expensive technology, today it is a technology that is taking root in almost every industry. Its prices are going down, and now even freelancers can afford to print models 3D for their personal needs .

Today, a variety of new 3D printing technologies have been added to stereolithography, with each technology having its advantages and disadvantages that allow 3D printers different industries in the industry.

To read more in the complete 3D printing guide, go to the chapter on Various 3D printing technologies .

- Chapter 1

What is 3D printing and what are its origins? - Chapter 2

The uses and purposes of 3D printing - Chapter 3

3D Printing Process - Chapter 4

How to choose 3D printing technology - Chapter 5

Overview of various 3D printing technologies - Chapter 6

General design guidelines for 3D printing - Chapter 7

CAD software classification - Chapter 8

3D Printing STL files: Introduction - Chapter 9

Understand common STL files errors and how to fix them - Chapter 10

SLS to MJF comparison - Chapter 11

Metal 3D Printing: Introduction - Chapter 12

How 3d metal printing change the world - Chapter 13

Metal 3D Printing Pros & Cons

- Chapter 1

What is 3D printing and what are its origins? - Chapter 2

The uses and purposes of 3D printing - Chapter 3

3D Printing Process - Chapter 4

How to choose 3D printing technology - Chapter 5

Overview of various 3D printing technologies - Chapter 6

General design guidelines for 3D printing - Chapter 7

CAD software classification - Chapter 8

3D Printing STL files: Introduction - Chapter 9

Understand common STL files errors and how to fix them - Chapter 10

SLS to MJF comparison - Chapter 11

Metal 3D Printing: Introduction - Chapter 12

How 3d metal printing change the world - Chapter 13

Metal 3D Printing Pros & Cons